TECHNOLOGY FEATURES

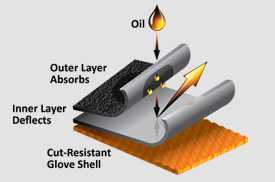

OIL RESISTANT

OIL RESISTANT

The leather is coated in a material that resists oil and petroleum degradation. The core function of oil-resistant gloves is to offer maximum grip to the mechanical workers as lifting & working with greasy objects is a routinely part of the job.

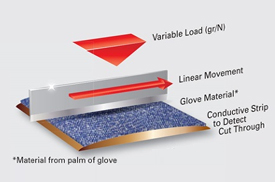

CUT PROTECTION

CUT PROTECTION

Cut-resistant gloves come in varying thicknesses & are made of the following fibers and materials.

Fiber metal blends—durable, cut- and abrasion-resistant.

Kevlar aramid fiber—flexible & lightweight, 5 times stronger than steel, low FR.

Spectra fiber—flexible, cut & abrasion-resistant even when wet; It is 10 times stronger than steel.

Dyneema—floats on water, durable & resistant to moisture and chemicals; It is 15 times stronger than steel.

Cut-resistant gloves are evaluated against the standards set by ISO 13997:1999 & the EU standard EN388.

ACTIVE GRIP TECHNOLOGY

ACTIVE GRIP TECHNOLOGY

Active Grip Technology (AGT) is a proprietary glove coating formula that provides industry leading wet, dry and oil grip. A secondary water resistant 3/4 coating is added underneath the AGT to ensure hands stay dry, making them ideal in wet environments and applications.

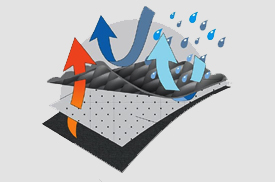

BREATHABILITY

BREATHABILITY

Keeping hands cool is critical for comfort and improved wearer compliance. Only selected materials that allow air flow are used to ensure 360 degree air circulation and enhanced breathability.

ANTI VIBRATION

ANTI VIBRATION

Force360’s silicon gel based Gel Pan 3.5mm padding is strategically placed to absorb vibrations and improves grip in heavy conditions. It performs exceptionally well with heavy duty power and pneumatic tools.

PVC FREE HEALTH FIRST

PVC FREE HEALTH FIRST

No Polyvinyl Chloride (PVC) is used in the manufacture of this glove. PVC is a known human carcinogen and contains several dangerous dioxins.

WATERPROOF GLOVES

GLOVES

If you wear a pair of our waterproof gloves you are 100% protected against moisture and water and you will stay dry and comfortable, even if your hands are working underneath the water surface. All seams are sealed and there are no leakage points.